Curtin University researchers will play a key role in a major new national push to strengthen Australia’s advanced manufacturing capabilities through next-generation 3D printing technologies.

The Additive Manufacturing Cooperative Research Centre (AMCRC) brings together universities, industry partners and government to build a nationally connected additive manufacturing ecosystem, aimed at transforming sectors including defence, aerospace, healthcare, automotive and construction.

Additive manufacturing – also known as industrial 3D printing – is the process of building products layer by layer from digital designs, enabling the creation of lighter, stronger and more complex parts with less waste.

Curtin’s expertise in materials science, materials characterisation, corrosion and advanced manufacturing will be central to the AMCRC’s work, with researchers from the John de Laeter Centre and the Curtin Corrosion Centre working alongside major industry partners including Austal – one of Australia’s leading shipbuilders – to deliver industry-led innovation.

Curtin University Deputy Vice-Chancellor Research Professor Melinda Fitzgerald said the AMCRC would accelerate the shift towards smarter and more sustainable manufacturing industries in Australia.

“Additive manufacturing is reshaping the way products are designed, built and delivered across the world,” Professor Fitzgerald said.

“Curtin is proud to contribute to this national initiative, helping to drive cutting-edge research that will advance Australia’s sovereign manufacturing capability and unlock new economic opportunities.”

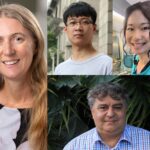

Curtin researchers Dr Karl Davidson and Associate Professor Zakaria Quadir from the John de Laeter Centre, and Associate Professor Kod Pojtanabuntoeng and Professor Vladimir Golovanevskiy from the Curtin Corrosion Centre, will represent the University on AMCRC projects.

Dr Davidson said the AMCRC has opened the door to major advances in materials science and manufacturing innovation.

“Over the next decade, additive manufacturing is poised to transform supply chains, increase production efficiency and reduce waste,” Dr Davidson said

“Our teams at Curtin will be applying world-leading expertise to develop stronger, lighter, and more sustainable materials for use in industries like defence and marine engineering.”

Associate Professor Quadir said Curtin’s world-class research facilities and industry scale large 3D printing platforms offer a strong opportunity for Western Australia to advance in manufacturing research.

Through its collaboration with partners, Curtin will support projects focused on mining, agriculture and marine-grade additive manufacturing technologies – helping deliver sovereign capability in critical sectors, including defence.

Funded with $58 million from the Australian Government’s Cooperative Research Centres program, the AMCRC will bring together 14 research partners and more than 50 industry collaborators to drive innovation, commercialisation and skills development over the next seven years.